Overview

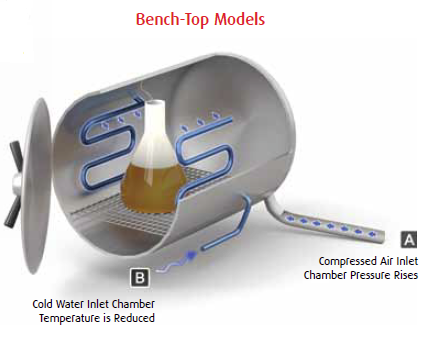

With higher capacity and better performance, Tuttnauer’s EL Laboratory line of fully automatic, microprocessor controlled, benchtop, steam sterilizers provides safe, economical and effective sterilization. Integrated reservoir for water feed, with water level control and steam recirculation saves on demineralized water consumption and enables the autoclave to be independent of a water supply. External heating elements make the sterilizer easy to clean.

These Tuttnauer benchtop front loading laboratory autoclaves are available in chamber sizes from 23 liters to 160 liters. EL models have an advanced microprocessor based control panel.

- 23 to 160 liter chambers

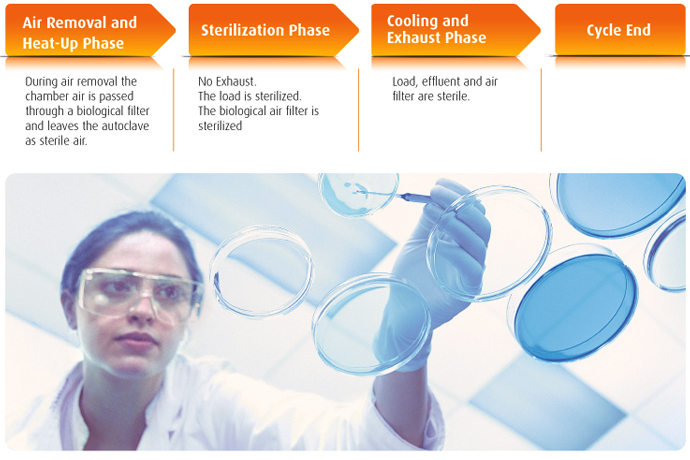

- Sterilizes liquids, solids, glassware and biohazard

- Advanced microprocessor control panel

- Independent temperature and pressure monitoring

- Independent digital and mechanical door safety features

- Chambers constructed of 316Ti grade stainless steel