Choosing a detergent will depend on a combination of three considerations: the utensils being washed, the users, and the washer disinfector cleaning procedure.

Detergents are designed to simplify your work by eliminating manual washing and reducing your manpower. Ensuring the safety of your patients by providing consistent quality washing cycles at all times and ensuring the safety of your staff by eliminating risks of exposure to potentially harmful aerosols.

Detergents help make the cleaning process even more effective. Essentially, they make the water wetter making it easier to trap residue away from the dirty equipment. This means that residue isn’t just moved around and that it is properly removed. The correct use of chemicals in washer machines ensures optimum washing results, saves money and environmentally friendly!

Manufacture instructions

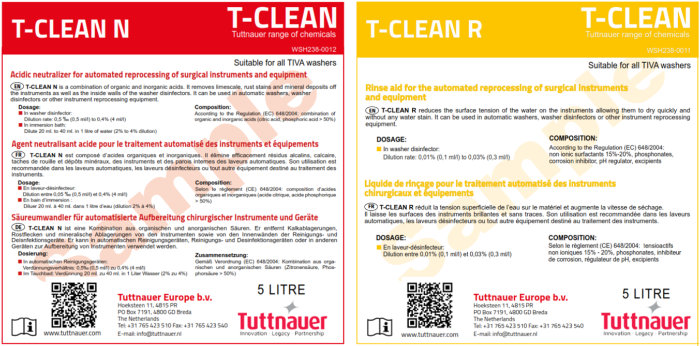

When selecting a detergent, it is important that the label claim of the cleaning agent you use specifies that the product can in fact be used as a cleaning agent for the reprocessing of medical devices. Finding a suitable detergent can be challenging or incorrect if the detergent does not have a clear label.

Additionally, the detergent’s IFU should be checked to make sure that the intended use of the cleaning agent is compatible with the intended medical utensils. For example, the T-Clean Alkaline Detergent is very suitable for anesthetic and endoscopic equipment, laboratory glassware. Whereas the T-Clean Enzymatic cleaner is used specifically for surgical instruments and endoscopes.

Manual soapy cleaning agents may generate too much foam during automated cleaning, thereby causing harm to the proper functioning of the washer-disinfectors. But even detergents intended for manual cleaning may not be suited for your specific manual cleaning procedure. For example, you may wish to wipe or spray the device even though the detergent’s IFU indicates that submerging the device is required for proper functioning of the detergent.

A final consideration is the compatibility of the detergent with the rest of your reprocessing instructions, more specifically if your instructions include high-level disinfection. Not all high-level disinfectants are compatible with all cleaning agents. Hence, the IFU of the disinfectant should be checked to see which detergents can be used in the cleaning phase. If compatibility issues exist with the intended detergent either another detergent should be selected or a rigorous rinsing step after cleaning should be introduced.

Geography of the user

Selecting a detergent will not only depend on your washer disinfector instructions, but also on where the users of your device are located. Several detergent classes exist such as alkaline, neutral pH, enzymatic, etc. and based on the location of your users they may have access to different detergent classes. It has been noted that the majority of healthcare facilities in the USA will rely on enzymatic detergents, whereas European healthcare facilities will mostly use alkaline detergents. It is important to note that enzymatic alkaline detergents like the T-Clean E can be used to cover both the EU and US markets.

Device materials

Keeping the reprocessing instructions and the location of the users in mind, a final consideration is whether the selected detergent is compatible with the materials used in the construction of the device. For example, devices containing aluminum can sustain surface damage when exposed to some alkaline cleaning chemicals. The detergent selected should not affect the compatibility or functionality of the device. The T-Clean Tuttnauer detergent line is completely compatible with the Tuttnauer TIVA washer disinfector line.

In summary, selecting the proper detergent will depend on the reprocessing instructions, the location of your users, and the materials used to construct the device. The IFU of the detergent you wish to use should always be checked to make sure that it is appropriate for the intended reprocessing instructions and that it is compatible with your device’s materials. Detergents are critical to ensure you keep your equipment hygienic and shining. There is a good reason why detergents have so many different compositions, because many factors must be considered such as temperature, wash cycle time, water pressure.

Author: Tuttnauer Product Experts

Tuttnauer Team is made up of veteran staff at Tuttnauer that are responsible for communicating with our customers about sterilization and infection control. Let us know if there is anything specific you want to read more about.