Sterilization in today’s infection control environment has taken on a new level of safety. Increasing the risk of infection spread is precisely what laboratory technicians need to avoid, and when dealing with microorganisms, it is critical to understand what your autoclave can do for you.

In the USA alone, there are over half a million laboratory employees, each potentially risking their health and safety with exposure to infections. The potential exists for bacteria and viruses to spread in a laboratory environment. That is why sterilization devices, like autoclaves, are such a critical component within any laboratory environment.

Laboratory autoclaves are designed for research facilities, universities, food, and microbiology settings. These autoclaves must be able to provide high quality, dependable performance that will allow for effective support of cutting-edge life science research.

The following article examines key features to consider when purchasing a laboratory autoclave. By the end of this article, you will be able to answer the following questions:

- Why are biohazard filters necessary for waste sterilization?

- Why are PT 100 sensors necessary for sterilizing liquids?

- When is Vacuum-Assisted Air Removal used?

- What are the benefits of advanced reporting software?

F0 control for heat-sensitive liquid media

Many of Tuttnauer’s LabSci laboratory autoclaves can perform cycles with F0 control (pronounced F Sub-Zero) *. This feature reduces the exposure time of the load to high temperatures. It is especially relevant when sterilizing delicate heat-sensitive liquid media. By minimizing the time liquid media are exposed to high temperatures, the integrity of the load is maintained and the cycle time is reduced. The theory behind F0 is that microorganisms and bacteria can be destroyed prior to reaching the set sterilization temperature, during the heat up stage, allowing for shorter sterilization exposure times.

How does F0 work?

F0 will adjust the sterilization hold time according to the F0 value, which depends on time, temperature and the Z-Value (thermal resistance) of the specific microorganism. This option reduces sterilization hold time according to the F0 value. If a standard sterilization holding time is set to 15 minutes, the sterilization hold time may be reduced, based on the F0 calculation, by minutes. This results in saved time and avoids overheating the liquid, while still ensuring appropriate sterilization.

Waste sterilization with biohazard filters

Does your laboratory work with Covid-19 test samples or biohazardous material? Autoclaves generate aerosols during the sterilization process. These aerosols may potentially contain harmful pathogens carried from the processed load. Therefore, the sterilization of biohazardous waste may put at risk both the staff as well as the surrounding environment. It is essential to have an appropriate sterilization solution that provided protection from this potentially harmful aerosol. With this in mind, it is highly recommended to equip the autoclave with an advanced air filter.

How does it work?

During the pre-sterilization air removal and heating stage, the chamber air being removed is passed through a microbiological filter that filters harmful substances before it is release to the air outside the autoclave. Air is filtered by a High-Efficiency Particulate Air filter, known as a HEPA filter. HEPA filters are used to block the passage of microorganisms found in the autoclave effluent. The destruction of pathogens caught inside the filter not only eliminates them and maintains the sterile conditions of the surrounding lab, but it also allows for safe, sterile conditions for the next autoclave cycle to be performed. Tuttnauer’s LabSci horizontal and vertical autoclaves are optionally equipped with a HEPA air filter that blocks microorganisms from exiting the autoclave during the air removal phase. This protective measure prevents the contaminated chamber air from escaping into the atmosphere and, instead, catches the harmful microorganism inside the filter.

PT 100 Sensors (Load Probes):

There is a significant gap between the load and the chamber heating time when sterilizing liquids, the former being significantly slower than the latter. The temperature in the chamber reaches sterilization conditions long before the liquid. For example, the chamber temperature may reach 121°C, initiating the sterilization phase; however, the liquid has not yet reached sterilization temperature. Therefore, the process will not be valid. Our autoclaves provide for two PT100 sensors to be placed within the liquid, ensuring the sterilization phase will only begin, when the liquid reaches the pre-set sterilization temperature. Furthermore, the sensors ensure that the load is cooled down to a safe temperature, protecting the staff when opening the autoclave door. Most laboratory autoclaves contain only one PT100 probe. However, Tuttnauer’s LabSci autoclaves, provide a solution beyond the required standard. All our sterilizers incorporate advanced technological features, providing safe and validated sterilization.

Sterilizing glassware and hollow instruments

When sterilizing glassware, hollows, and pipette tips, it is essential to remove the air before sterilization, to maximize steam penetration. These loads inherently contain air inside the vessels, and this air must be removed to ensure complete sterilization of the load. Using a vacuum pump provides greater sterility assurance, by mechanically removing the air from the chamber and load, via pre-vacuum air removal pulses. The vacuum pump also helps to dry the load more efficiently.

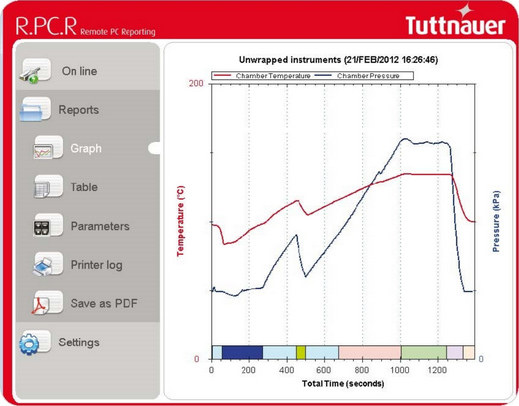

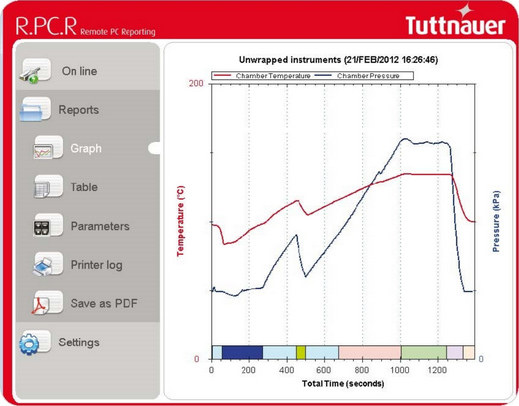

User-friendly control system and advanced R.PC.R. software

The advantages of a state-of-the-art Control System with Multi-Color Display include:

- F0 software control

- 200 Cycles storage

The Tuttnauer R.PC.R software is an essential addition to research and laboratory autoclaves. It performs automatic cycle monitoring and can be used over the local area network. It is a user-friendly report generator that enables you to:

- Manage cycle history report files online or offline by USB

- Track the entire history of the processes run by the autoclave

- Track-specific parameters that have been used in each cycle and stage

- Choose a reporting style including graphs, tables or printouts

- Generate PDF reports

The control system and RPCR software comply with the 21 CFR part 11 standard.

Tuttnauer, a global sterilization solutions expert, has developed a unique and competitive laboratory sterilizer series. The LabSci product line is a robust, reliable and cost-effective solution for all your laboratory sterilization needs.

These sterilizers are designed to provide high quality repeatable performance and accountability for a wide range of lab applications, including: liquids, media, glassware, instruments, clothing, waste, and other laboratory items.

The LabSci line offers a wide range of models and sizes, from compact benchtop machines to vertical and freestanding sterilizers. These models include electronically controlled sterilizers, some with pre-post vacuum technology, innovative control systems and much more. All LabSci models comply with the highest manufacturing and safety standards and are provided with a built-in printer for GLP-compliant documentation.

About Tuttnauer: Tuttnauer provides end to end sterile processing solutions for laboratories, research institutes, hospitals, medical, dental and ophthalmic clinics, including; advanced autoclave, washer-disinfectors, indicators, and sterile processing products. The safe and reliable biocontainment systems are designed to deal with the environmental threat posed by pathogens and other contaminated materials emitted from laboratories. Tuttnauer takes the most extreme measures in fighting bacteria and viruses, including the Coronavirus (aka SARS-CoV-2), by providing innovative decontamination solutions that go above and beyond the required standards.

For further information and to inquire about purchasing an advanced autoclave for your laboratory, contact a Tuttnauer representative.

Author: Tuttnauer Product Experts