By Ad Geilings, Global Product Manager Laboratory

Water is the lifeline of an autoclave. It is the most critical component of a steam autoclave. Sterilization will not happen in a steam autoclave without water. Steam sterilization uses saturated steam to the items in the autoclave. The steam comes into contact with the items placed inside the autoclave. In the case of packed surgical instruments, for example, the steam must permeate the pack wrappings and heat the instruments inside the packs. For this reason, steam must be free from impurities in order to avoid staining or corroding the items being autoclaved.

Water can damage stainless steel instruments. Stainless instruments are susceptible to pitting in several scenarios; an increase in the chloride content in the water, or when there is an increase in temperature, with decreasing pH values, increased exposure times, insufficient drying and concentration of chloride from dry residues to instrument surfaces after evaporation.

The type of water you use can dictate the types of loads you can sterilize and affect the lifespan of your autoclave chamber and steam generator significantly.

Since autoclaves are costly investments, it is crucial that it is used appropriately and maintained regularly, especially autoclaves that are used very frequently.

The leading question almost every autoclave operator asks, is can I use tap water in my autoclave?

The answer is NO. Tap water, even when its potable water, is generating low quality steam, which is not suitable for a proper sterilization.

There are several things that can affect water quality: its hardness, its minerality, whether it contains chlorides. Using tap water might be common practice for some, however this will most certainly lead to costly downtime and expensive repairs over time, if the water quality is inadequate. Tap water is certainly a practical source for creating steam, but it can also be destructive to your autoclave.

It is important to note that the water quality requirements for safe drinking water are often different from the water quality requirements of industrial machinery. If your municipal water quality report does not indicate the hardness of your tap water, we recommend that you perform an independent water quality test. Ideally, whether you have the municipal water quality report or not it is ideal to test the water right before it enters the steam boiler as building pipes can contribute to water hardness.

Damage to your autoclave caused by water:

Tap water contains a variety of dissolved minerals and salts. Depending on your geographic location and water source (e.g., ground well, lake, river, etc.) the amount of dissolved substances can be very high. The more minerals water contains, the “harder” it is. When hard water is boiled into pressurized steam, it leaves behind salt and mineral deposits within the steam generator, pipes and valves. These deposits build up over time like layers of paint. As they build up, they decrease the efficiency and functionality of the steam generator, as well as clogging up pipes and valves.

Your autoclave chamber should be shiny from the stainless steel, any coloring, white spots, or rusting is a clear indication of poor water quality causing damage to your autoclave operation.

Scale can wreak havoc on a generator. Scale is caused from chemicals that are deposited onto a surface and create a hard layer. Scale can form inside water level sensor tubes, which can cause the sensor elements to malfunction. This can potentially lead the heaters to melt down and fail.

Alternatively, scale could flake off and fall into the shell of the generator, or stay stuck to the surface, where it can form calcium deposits. These calcium deposits are electrically conductive and can create bridges between heaters, which can, again, cause them to short circuit and overheat.

Given the potentially dangerous consequences, it is important to be mindful of the water quality used for your autoclave device.

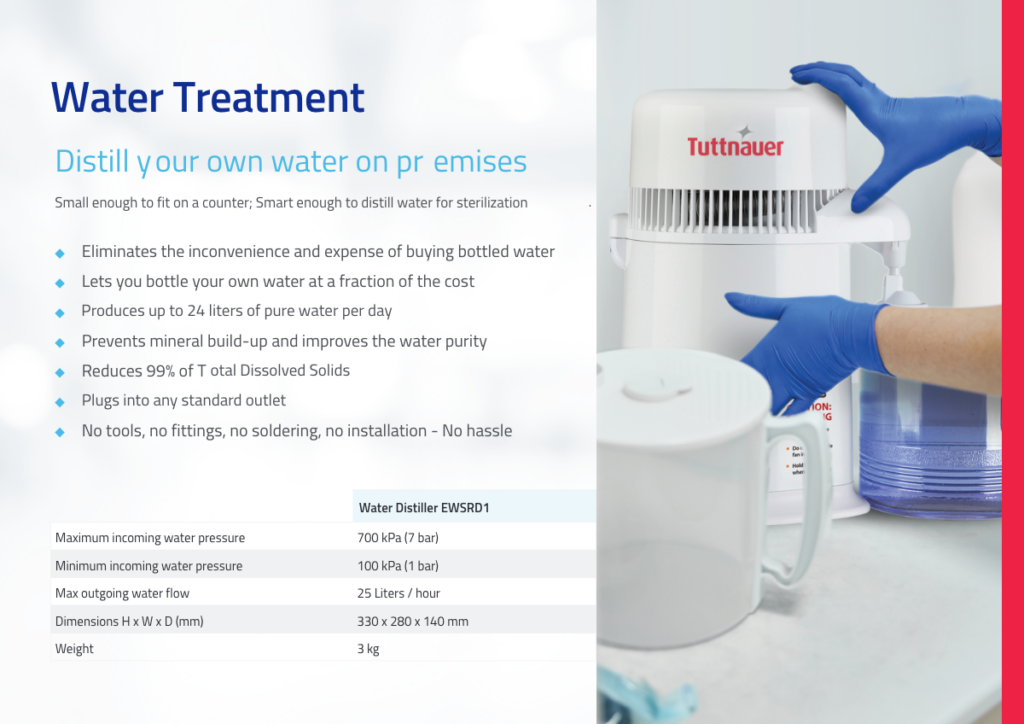

Tuttnauer offers several water treatment products, the water treatment system supplies the autoclave with demineralized water and provides the basis for maintaining the value of the autoclave.

The Tuttnauer water treatment units deliver a number of advantages: providing value-for-money, it is an environmentally friendly and highly effective method with which to produce demineralized water of a constantly high quality.

Other methods of purifying water

Carbon Boilers:

- Reverse Osmosis (RO) – RO systems filter water by forcing it through a thin permeable membrane that removes most solid contaminants and dissolved minerals but does not remove biological particles, such as bacteria or viruses. An RO system is the #1 recommended solution for standard carbon steel boilers.

- Another option for carbon steel boilers is the use of a water softener system. These systems are a chemical treatment that reduces hardness, but can leave other impurities dissolved in the water, so is only applicable to customers who meet all water quality requirements except for hardness.

Stainless Steel Boilers:

- Deionization (DI) – DI systems remove the ions from the water and produce a very high purity level. It does not affect uncharged molecules, viruses or bacteria. Deionized water should only be used to feed stainless steel boilers.

- Distillation – Distillation removes virtually all impurities from water by boiling it and then condensing the steam into a clean container. This process removes virtually all dissolved materials. Distilled water should only be used to feed stainless steel devices.

Fixing an autoclave that is damaged by poor water quality

There are several options based on the severity of the damage. For minimal damage use the automatic generator blow-down feature to drain out scale, especially for any carbon steam boiler that isn’t fed with purified water.

The second option is to implement a water filtration system, like the Type IV RO filter mentioned above. This water system, which is a step up in complexity from the kind you’d find under your kitchen sink, will remove minerals from your generator and feed it more purified water. This is an acceptable response to all but the most severe cases.

The third option based on severe damage is to purchase a new autoclave. This level of damage is most common in areas of very poor water quality where scale likely built up over the course of a few years.

Generally, it is always a good idea to use good quality cleaners for your autoclave, to remove accumulated residue. Tuttnauer offers a variety of cleaners that will assist in maintaining the longevity of your autoclave investment. https://tuttnauer.com/consumables/cleaning-materials

Water contaminants that may have a negative effect on autoclaves

- Ions – Calcium and magnesium salts are less soluble in hot water than in cold water. This leads to scaling, which is the main concern for autoclaves. Carbonate deposits are usually porous, while sulfate deposits tend to be much harder and dense. Scale deposits inside hot water pipes, boilers and heat exchangers restrict water flow and reduce heat exchange efficacy.

- Metals – Iron, copper and manganese may also form deposits in the steam generator and reduce heat transfer. In addition, they can generate discoloration and stains of the instruments being autoclaved.

- Particles – They may form deposits in the steam generator or in the instrument and alter their functioning. They may also contaminate the solutions or instruments being autoclaved.

- Bacteria and their by-products – Levels of bacteria and endotoxins should be minimized in the steam feed water of autoclaves, as there is a risk that they may be deposited onto the items being autoclaved. Although steam sterilization inactivates bacteria, it does not fully inactivate their by-products, such as endotoxins. Endotoxins may affect experiments (such as cell culture, etc.) or patient care (by causing inflammation and delaying wound healing).

- Chlorides – They lower steam efficiency. When present in large quantities, they lead to uneven steam delivery and may provoke foaming in the steam generator.

ABOUT THE AUTHOR

Ad Geilings, Global Product Manager Laboratory

Ad has been working for Tuttnauer Europe from 1997 until 2001 as Technical Manager, he has been in senior roles as Managing Director Tuttnauer Europe for 20 years. As a global product manager Ad works very closely with the engineering and R&D team. Ad has been a member of Dutch Committee Sterilization & Sterility since 1997.